Biaxially oriented polyethylene terephthalate (BOPET) film is a material that is widely used because it is easy to process and has good overall performance. When a large amount of inorganic powder, such as silica, is mixed into the polyester film, it creates a matte finish. This matte finish gives the film a low gloss and high haze appearance. Matte films can be divided into three types based on their gloss or haze levels: high matte, medium matte, and low matte.

1. Where is it used?

Matte films are used in many different areas. They are common in release liners, which are the backing materials that protect adhesives. They are also used in hot stamping bases, which are needed for applying foil to materials like plastic or paper. Additionally, matte films are used in steel lamination, which involves bonding layers of material together. You can also find them in building decoration materials, household appliances, and precision equipment like computers.

As more industries discover the benefits of matte films, the demand for these films continues to increase every year. This growth shows that there is a big potential market for matte films. However, not all matte films are the same. They can differ a lot in how they are processed and how they look. Because of these differences, it is important to understand how much silica should be added to the film. The amount of silica can greatly affect the film’s final properties.

This information is valuable for manufacturers. It helps them create matte films that meet the specific needs of different industries. By adjusting the amount of silica, they can produce films with the right balance of gloss, haze, and other properties. As a result, matte films can be better tailored for their intended uses.

2. Research Methods and Findings

In this study, we looked at how different amounts of silica affect the properties of matte films. We used two types of polyester: super bright polyester and matte polyester. We then tested how these films behaved when different amounts of silica were added. Our tests focused on three main areas: thermal properties, tensile properties, and optical properties along with surface roughness.

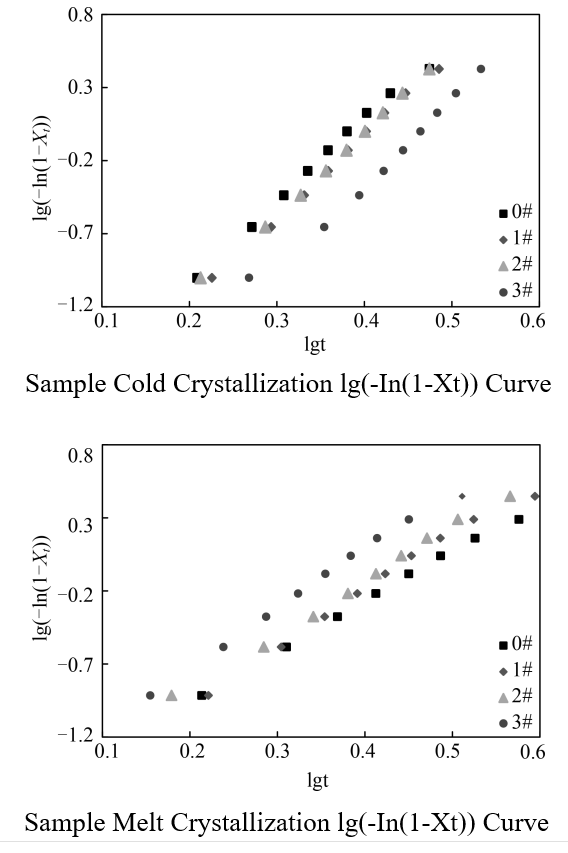

2.1 Thermal Properties

We found that when more silica was added to the film, the crystallization temperature of the matte polyester decreased. This means that the film started to crystallize at a lower temperature. Silica has different effects on cold crystallization and melt crystallization. As the amount of silica increased, the Avrami index (n), which relates to how the film crystallizes when heated, went up. At the same time, the half-crystallization time (t1/2), which measures how long it takes for the film to crystallize, went down. In simple terms, adding more silica made the film crystallize faster during the heating process.

2.2 Tensile Properties

To see how the films stretched, we used a biaxial stretching machine. This machine pulled the films in two directions at the same time. All the samples we tested showed that they were very elastic, meaning they could stretch without breaking easily. None of the samples had a clear yield point, which is the point where a material starts to deform permanently. As we added more silica, the force needed to stretch the film increased. This means the films became stronger and harder to stretch. We also noticed that the higher the stretch ratio (how much the film was stretched), the more the amount of silica affected the force needed to stretch the film.

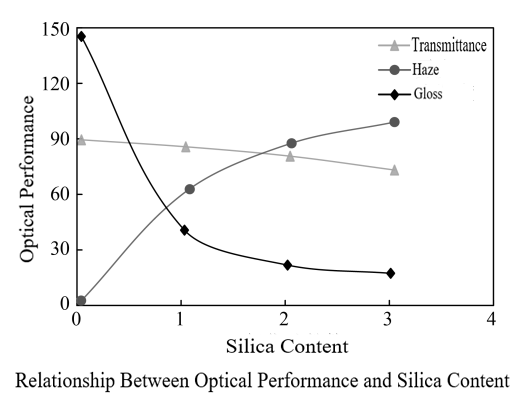

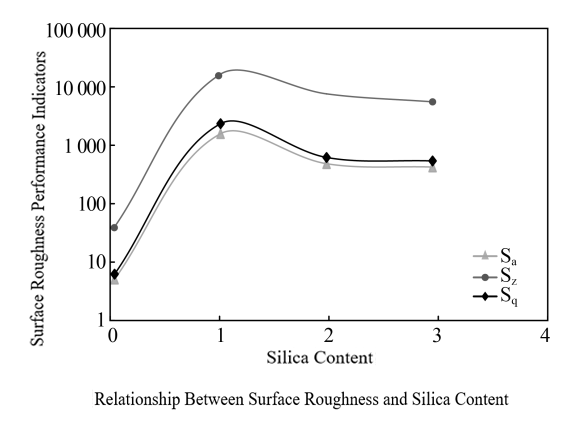

2.3 Optical Properties and Surface Roughness

The amount of silica added had the biggest impact on the gloss of the matte films. Gloss is how shiny or reflective the film is. After gloss, haze (how much the film scatters light) was affected the most, and transmittance (how much light passes through the film) was affected the least. Adding silica also changed the surface roughness of the films. The film with 1 part of silica had the roughest surface, making it feel less smooth. But as we added more silica, the surface became smoother. This suggests that if too much silica is added, the film’s surface might become too smooth, which could reduce the matte effect that we want.

3. Conclusion

The amount of silica in matte polyester film is crucial in determining its properties. A moderate amount of silica can improve the roughness and tensile strength of the film. However, if too much silica is added, the film surface may become too smooth, reducing the matte effect. These results are useful for designing matte film formulas and improving production processes.