In manufacturing, quality is everything.

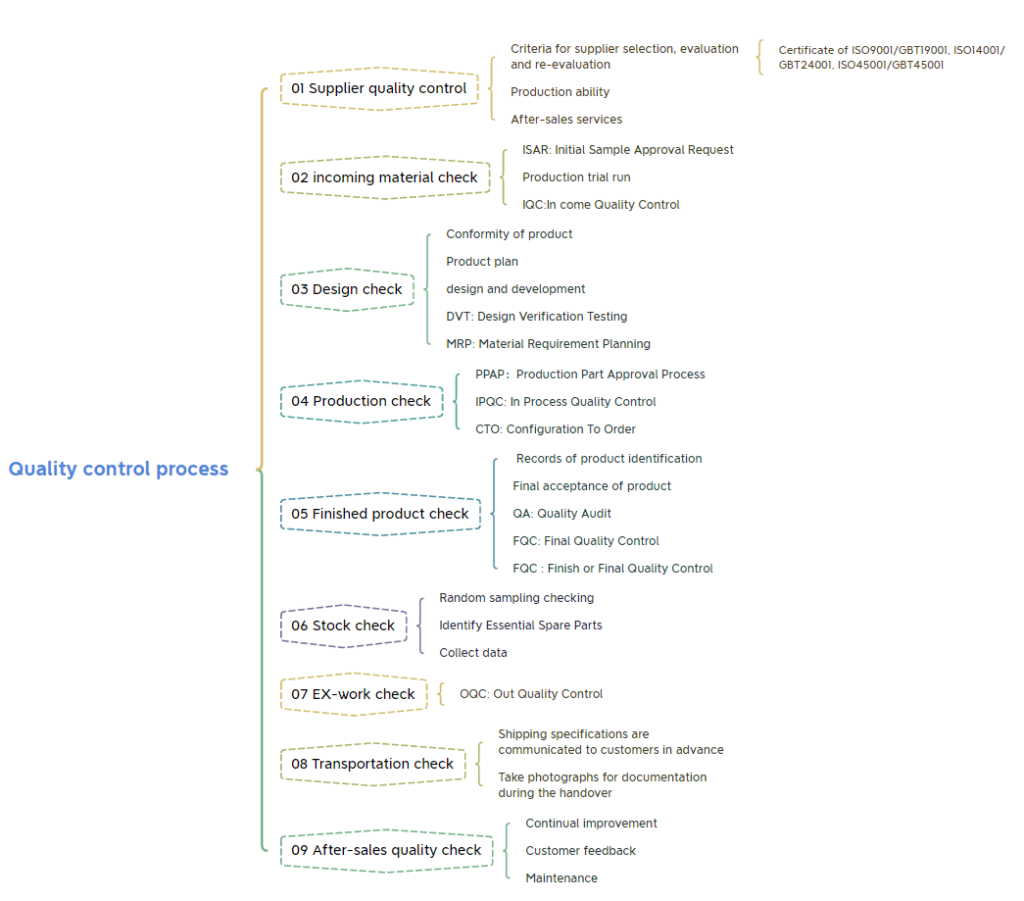

We follow the entire production cycle of our products, from supplier quality control, incoming material check, design check, production check, finished product check, storage check, EX-work check, transportation check, to after-sales service check, to ensure comprehensive quality control. We have established a traceability system.

Following is our quality control process and standards:

We put quality first. From product production to sales, quality is reflected everywhere. We put quality first. From product production to sales, the shadow of quality exists everywhere

Supplier Selection

To begin with, supplier selection is of utmost importance to us. We will only cooperate with suppliers with good qualifications, including ISO9001, ISO14001. Their products should comply with national and industry standards. Suppliers must provide timely and effective after-sales service. Supplier selection is the first checkpoint, so their quality standards are the best.

Incoming Quality Control

Material management is also crucial in our quality control process. We conduct strict inspections and records on each batch of raw materials, including physical properties, chemical composition and so on. In this way, the supplier’s product can compliance with our standards. It also guarantees the availability and quality of materials.

Design Control

During the design and production phases, it is important to have clear and standardized documentation. Clear design and production documentation is essential to prevent misunderstandings and errors. Our team must adhere to a standardized build and testing process, which helps us analyze results and plan improvements.

Production Control

During the production process, employees keep the work area clean and orderly. This not only improves efficiency but also minimizes the risk of accidents. Employees should follow safety protocols. We provide basic first aid instructions in work areas to ensure a quick response in the event of injury.

We have a strict traceability system, so we can trace every product and process. In our warehouse, spare parts for each product are strictly numbered and managed. If there is any need from the client after sales, we can easily find the corresponding spare parts even time passed.

Throughout the whole quality management process, it is important to use data. From the data, we can examine for ourselves what is better and where we can improve. By analyzing the results, we can make more improvements from there. We develop action plans based on data to continuously improve our quality standards.

Datasheet

By using a strict quality control system, the success rate is significantly improved. According to annual data, our success rate has reached 99.8%, so only 0.2% of our products have quality problems. They have data to help improve. These figures reflect the efficiency of our quality management standards and processes. Besides, our employees active involvement also matters.

In addition, we also collect customer satisfaction data. According to annual data, more than 95% of customers are satisfied with our products and after-sales services. This demonstrates the effectiveness of our quality control measures. Our commitment to providing exceptional service is what makes us successful.

National Standards

National standards provide clear guidance for the quality control of polyester chips. It ensurs that our products meet the requirements of domestic and international markets.

Our products strictly comply with GB/T 1040-2006 “Test of tensile properties of plastics”, GB/T 2918-2018 “Test of impact resistance of plastic sheets”, GB/T 9341-2008 “Test of tensile strength of plastic slices”, GB/T 4454-1996 Plastic sheet transparency test, GB/T 13541-2005 Plastic slice molding test, GB/T 2829-2002 Sampling method and sample preparation and some other standards.

It improves product quality, reduces quality risks, and ensures the market competitiveness of products