The successful production of film-grade PET chips depends on several key factors. We will show you the difference in the manufacturing process, viscosity, melting point, DEG content, COOH content, and agglomerate particle size. Each indicator impacts the production of BOPET films.

Production Process

It adopts an external additive process. The additive content between batches should be relatively stable. The fluctuation range should be controllable. If the additive content fluctuates too high, it will affect the active homogenization and dispersion of the additive. If the additive content is too low, the cost increases.

Viscosity

The relative molecular weight affects the strength of the film. When the viscosity reaches a certain value, the strength will no longer increase. Fluctuation of viscosity ±0.02.

To make the film-grade slices and white slices compatible and meltable, the IV is better in the same value range. If the difference is too large, it will affect the uniformity of the optical properties of the film. It also affects the production.

The molecular weight distribution should be narrow, with the molecular weight ranging from 16,000 to 18,500. When we ensure the molecular weight distribution, we can significantly ensure the stability of viscosity and production.

We have different IV pet chips used for BOPET film, Label Film, Anti-block Film and Packing Film.

Melting Point

The melting point of film-grade slices is generally required to be 260±1°C.

The low melting point causes uneven distribution of relative molecular weight, poor heat resistance of the resin. The film is prone to aging and brittleness.

Several transformation temperatures of PET chips:

- Glass transition temperature=68℃

- Cold crystallization exothermic peak temperature = 124℃

- Start of endothermic crystallization temperature = 225℃

- PET decomposition temperature=380-400℃

DEG Content

High Deg content lowers the melting point and affects heat resistance and light resistance.

It is more important to control the diethylene glycol content of the insulating film. Generally, it is 0.7-1.2%, and the fluctuation does not exceed ±0.02%.

COOH Content

COOH (Carboxyl) content is another critical factor. As high COOH content can impair the insulating properties of the film.

Agglomerate Particles Size

Affects the service life of the filter.

1. Slices without additives are required to reduce ash content. Generally <300ppm without coke materials and low molecular powder.

2. For slices containing additives, agglomeration of particles must be controlled. After the additive preparation liquid is stirred evenly, it passes through a 5-micron filter and enters the lipid ax for an esterification reaction. Before entering the polycondensation ax, it must be filtered again at a 15-20 micron level.

3. Conditions that PET additives must meet:

a. Have a defined particle size and particle size distribution range

b. Chemical stability during polyester processing

c. Diffuses in ethylene glycol

d. No agglomeration during polyester processing, meet product requirements for transparency, color, electrical insulation, and wear resistance

4. For films with different uses, it selects additives with different particle sizes and materials. It can improve the intrinsic and surface properties of the film.

5. Regarding the requirements for the use of additives, the different processing additives have different effects on film properties. Currently, there are mechanical production methods, gas phase synthesis production methods, surface treatment, flame treatment, and surface chemical treatment.

6. There are clear requirements for agglomerated particles, generally > 10um, <0.6/mg. Agglomerated particles < 10um, generally will not affect the normal production of films above 12 microns. But it will affect the use time of the melt filter.

Thermal Stability

1. It will not degrade when drying meets process requirements and the temperature is not overheated. There are no abnormalities in film production and appearance.

2. The main production processing temperature should be 270-290℃. The film performance and production are normal. Adjust the heat stabilizer to meet the process requirements. Check the viscosity by comparing the viscosity of the dried slices with the viscosity of the cast slices.

The above indicators explain the production requirements of PETchips in detail. These factors influence the properties of the films. They also affect suitability for diverse application areas. By controlling these parameters, produced high-quality BOPET films can meet the demands of various applications.

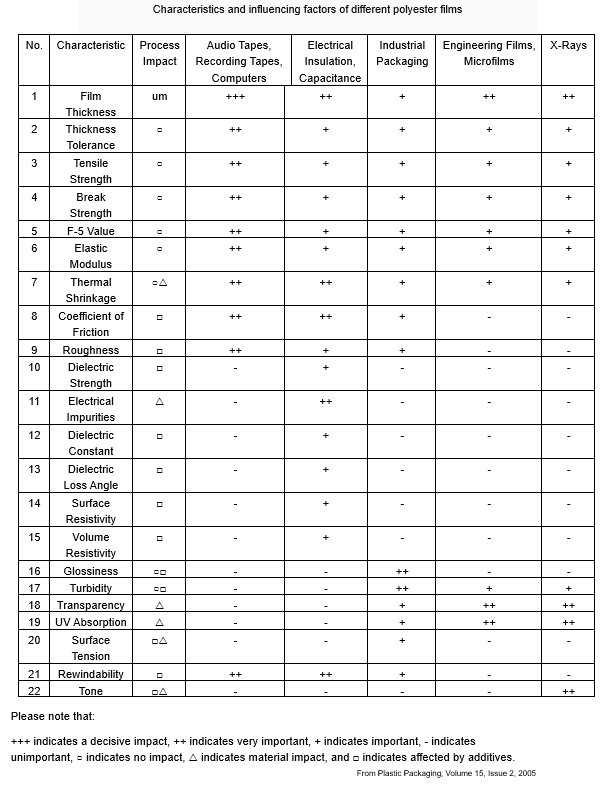

Characteristics and influencing factors of different polyester films