In the production of technical textiles such as industrial yarns, seat belts, and curtain fabrics, have you encountered these issues?

❌ Frequent yarn breakage?

❌ Fluctuating spinning pressure?

❌ High strength deviation and low product yield?

❌ Severe batch-to-batch variation in customer acceptance?

Don’t worry, HMLS Polyester Chips (High Modulus Low Shrinkage) are being increasingly selected by factories as the key material for improving production efficiency and stability.

1. The 3 key issues factories care about, and how HMLS chips solve them:

Issue 1: High breakage rate, low equipment utilization?

In spinning high-strength yarns, seat belts, and other applications, ordinary polyester chips often cause:

• Unstable melt pressure

• Sticky yarns and breakage

• Frequent machine cleaning, impacting production output

📌【Customer Case】

A woven tape factory in Jiangsu used ordinary chips, with a daily output of only 1.8 tons per line and a breakage rate of 8.5%.

After switching to HanLink HMLS chips (IV = 1.05, COOH ≤ 14):

✅ Breakage rate dropped to 3.1%

✅ Daily output increased to 2.2 tons per line

✅ Monthly savings on labor and maintenance costs exceeded thousand USD

Issue 2: Product strength not up to standard, poor batch stability?

Fabrics such as curtain fabrics and industrial webbing have high strength and heat shrinkage requirements:

Performance Parameters | Requirements

Tensile Strength | ≥ 7.5 cN/dtex

Heat Shrinkage (150℃) | ≤ 6%

Color Difference ΔE | ≤ 1.0

Ordinary chips have uneven molecular weight, leading to severe shrinkage, low strength, and inconsistent color differences.

📌【Standard Reference】

The “Q/CTESI 023-2021” standard issued by the China National Textile Research Institute specifies:

IV deviation ≤ ±0.01, COOH content ≤ 15 μeq/g as the foundation for stable spinning.

HanLink HMLS chips use continuous polymerization + SSP process:

✔️ IV deviation controlled to ±0.005

✔️ COOH ≤ 13 μeq/g

✔️ No pressure in high-speed spinning and coating processing!

Issue 3: Customers demand high performance, but ordinary chips fall short?

HMLS filaments have natural advantages, specifically designed for industrial-grade applications:

✅ High Modulus: Resistant to stretching, not easily deformed

✅ Low Heat Shrinkage: Strong dimensional stability

✅ Low Lag Loss: Rubber products less prone to heat accumulation

✅ Heat/Pressure Stability: Suitable for high-temperature heat pressing

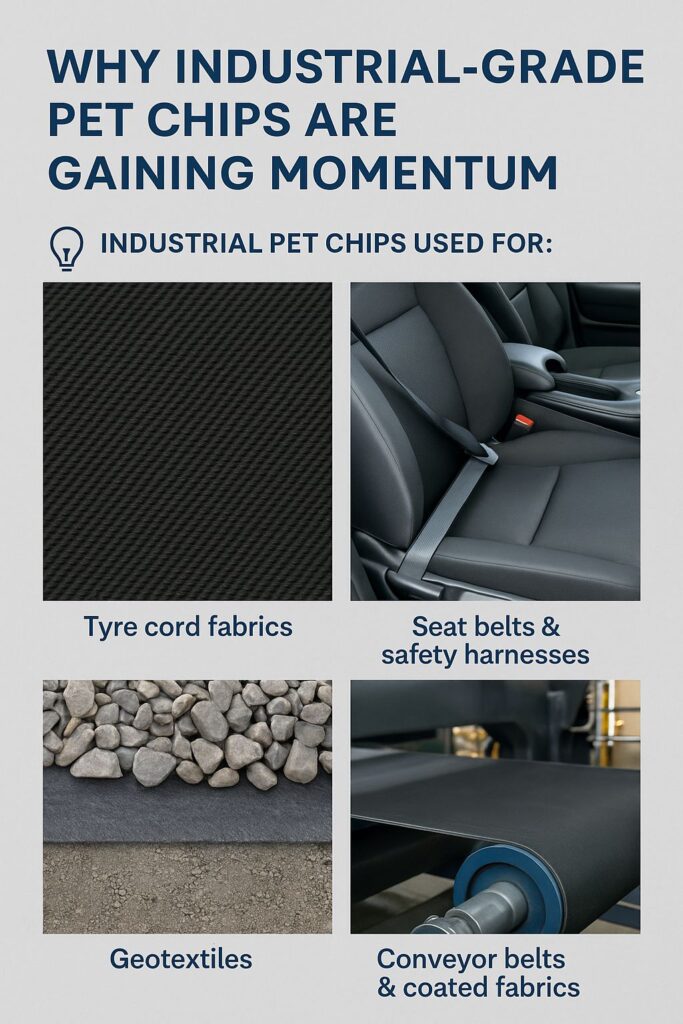

📍 Widely used in:

• Tire fabrics

• Seat belts & lifting straps

• Conveyor belts, V-belts

• Coating base fabrics

• Industrial-strength yarns

2. How are HMLS Polyester Chips Made?

🌱 Raw Material Selection

PTA (Purified Terephthalic Acid) + EG (Ethylene Glycol) + Catalysts & Stabilizers

🔥 Polymerization Process

• Esterification reaction → Producing intermediates

• Polycondensation reaction → High molecular weight polyester melt → Granulation into chips

🔁 Solid-State Polymerization (SSP)

• Washing to remove impurities

• High-temperature treatment → Increase IV, decrease COOH

• Controlling crystallinity → Ensure stability of yarn formation

3. Typical Parameters of HanLink HMLS Chips

Parameter | Range

Intrinsic Viscosity (IV) | 1.0 – 1.2

Carboxyl Value (COOH) | ≤ 15 μeq/g

Ash Content | ≤ 80 ppm

L Value (Brightness) | ≥ 68

b Value (Yellowing) | ≤ 7.0

Heat Shrinkage (180℃/2min) | ≤ 6.0%

Filament Tensile Strength | ≥ 7.8 cN/dtex

Data based on HanLink Testing Center, compliant with ISO 1628-5 and ASTM D2256 standards

4. Customizable Features to Support More Industry Applications

In addition to the standard HMLS chips, HanLink also offers:

• Low Carboxyl Chips: Higher dyeing consistency

• Phosphorus-based Flame Retardant Chips: Supports M1/VTM-0

• UV-resistant Modified Chips: Suitable for outdoor webbing, tent fabrics

• Enhanced Surface Polarity Chips: Better suited for coating & composite processing

Feel free to inquire, and let’s create high-performance industrial yarn solutions together!