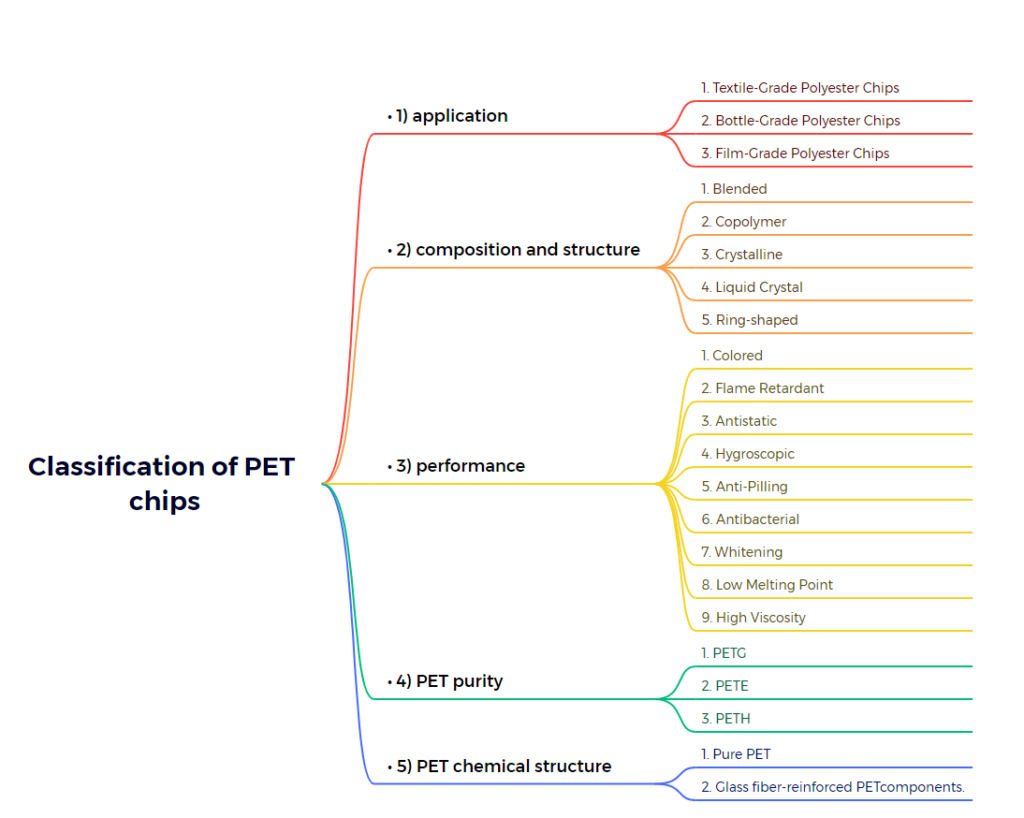

Polyethylene terephthalate (PET), abbreviated as PET, is a white granular solid formed by the polymerization of terephthalic acid (PTA) and ethylene glycol (EG). According to its application, composition, performance, purity and chemical structure, the calassfication is different.

Classification:

1) According to application

- Textile-Grade Polyester Chips: used in textiles, ropes, clothing

- Bottle-Grade Polyester Chips: used in plastic bottles, food containers, cosmetic bottles

- Film-Grade Polyester Chips: Used in packaging films, plastic bags, cling film

2) According to composition and structure

- Blended: Composed of different polymers blended together, combining various properties. Used in plastic products, composite materials, and packaging materials.

- Copolymer: Formed by the polymerization of multiple monomers, customizable for specific attributes.Used in plastic products, flexible materials, and sealing materials.

- Crystalline: Possesses a crystalline structure, offering high strength and rigidity. Used in high-strength components, and mechanical parts.

- Liquid Crystal: Features ordered molecular alignment, used in high-performance electronic materials.Used in display screens, electronic materials, and liquid crystal devices.

- Ring-shaped: Exhibits a ring-shaped molecular structure, utilized in special material research. Used in high-performance electronic devices, and material research.

3) According to performance

- Colored: Contains added color or dyes, suitable for colorful products. Used in colored plastic products, textiles, packaging.

- Flame Retardant: Possesses flame retardant properties, enhancing safety. Used in electronic devices, building materials, automotive components.

- Antistatic: Has antistatic characteristics, preventing static buildup.Used in electronic devices, antistatic packaging, cleanroom equipment.

- Hygroscopic: Absorbs moisture, suitable for humidity-sensitive applications.Used in medical devices, humidity-sensitive equipment, agricultural etc.

- Anti-Pilling: Resistant to pilling, maintaining appearance quality.Used in clothing, textiles, bedding.

- Antibacterial: Exhibits antibacterial properties, improving hygiene.Used in medical equipment, food packaging, textiles.

- Whitening: Provides whitening effects, enhancing visual appeal.Used in white plastic products, textiles, food containers.

- Low Melting Point: Has a lower melting point, used in heat-sensitive applications, like hot melt adhesives, sealing materials, thermosensitive materials.

- High Viscosity: Features high viscosity, improving adhesive performance.Used in adhesives, sealing materials, coatings.

4) According to PET purity

- PETG: Packaging, transparent parts, bottles, etc.

- PETE: Possesses higher heat resistance, suitable for microwave ovens and food containers, such as food containers, hot water bottles, thermoplastic engineering components.

- PETH: Offers improved impact strength and toughness, suitable for applications with bending and high impact loads, such as bottles, engineering components, electronic enclosures.

5) According to PET chemical structure

- Pure PET: without fillers or reinforced PET containing fillers like glass fibers.Used in bottles, fibers, films.

- Glass fiber-reinforced PET: provides higher rigidity and strength, suitable for structural parts.Used in mechanical components, automotive parts, ship components.

Here show all the classifications: