Polyester industrial yarns are popular because they are strong and durable. They are used in things like car curtain lines, conveyor belts, and safety belts. As safety concerns rise, flame-retardant polyester industrial yarns are getting more attention. While flame retardants improve fire resistance, they can also change the yarn’s structure and performance. So, it’s important to balance flame resistance with other properties like crystallinity, strength, and shrinkage.

1. Research Background

We studied how high-temperature pre-tension affects high-strength flame-retardant polyester industrial yarns (FRHT) compared to ordinary high-strength polyester industrial yarns (HT). We tested different pre-tension levels (from 0.05 to 0.70 cN/dtex) and treated the yarns at 195°C for 5 minutes. We focused on how this affected crystallinity, mechanical properties, and shrinkage.

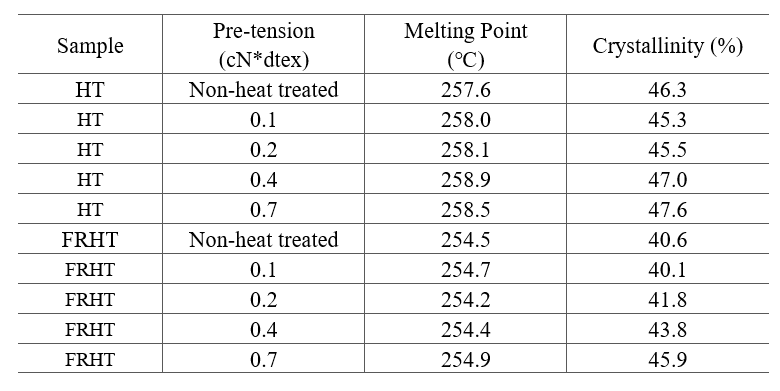

2. Crystallinity and Orientation

Our results showed that pre-tension affects the crystallinity of polyester industrial yarns. After treatment, FRHT had lower crystallinity and orientation than HT. This is because flame retardants interfere with crystallization. They reduce the movement of polymer chains, leading to lower crystallinity. Flame retardants also push out of crystallization zones. It reduces the orientation of amorphous regions. However, as pre-tension increased, chain reorganization improved crystallinity and orientation. At 0.40 cN/dtex, both crystallinity and orientation improved significantly, with FRHT showing strong results.

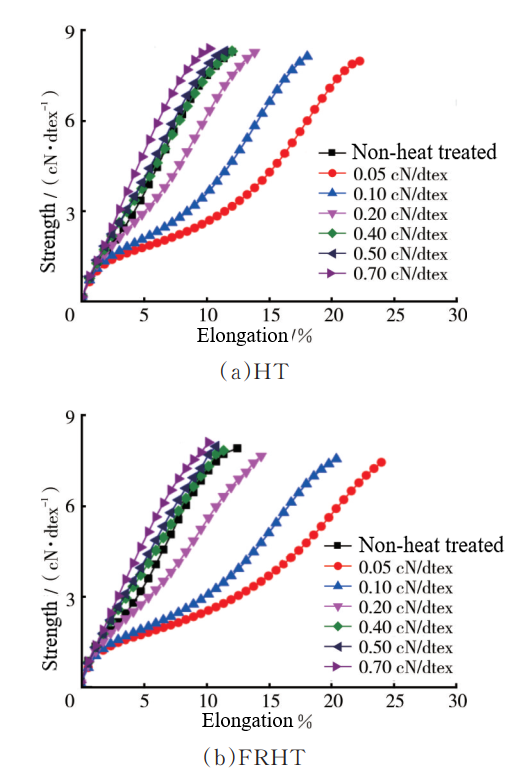

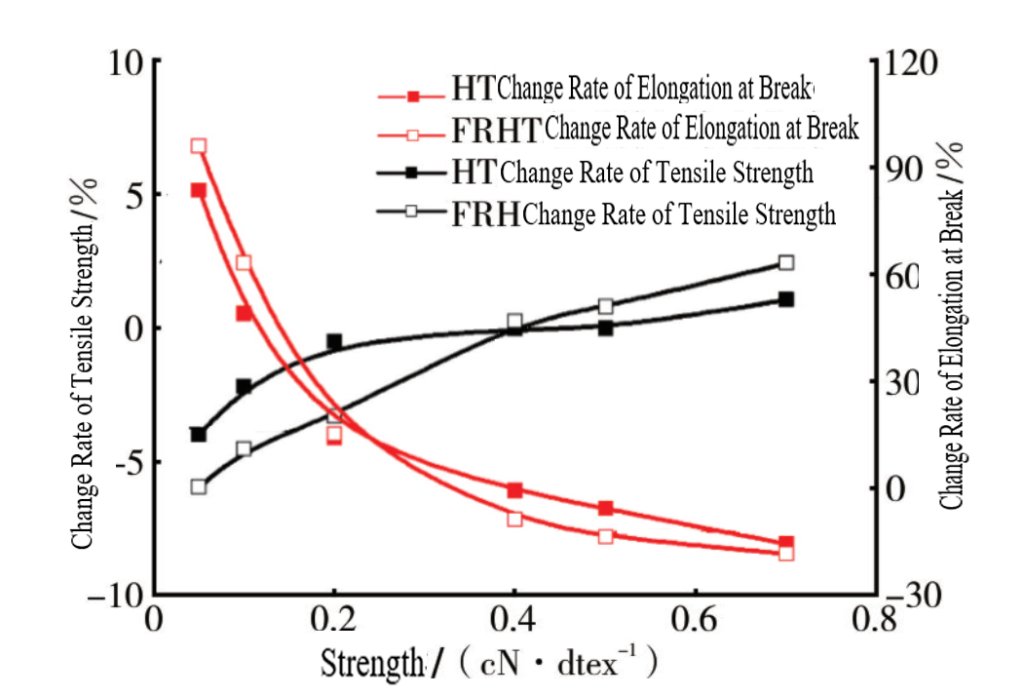

3. Mechanical Properties

In terms of mechanical properties, at lower pre-tension (0.05 to 0.20 cN/dtex), both FRHT and HT showed yielding in their stretching curves. This suggests that heat treatment improved chain movement in this range. As pre-tension increased to 0.40 cN/dtex, yielding disappeared, and both strength and initial modulus improved. FRHT showed higher strength and modulus under higher tension. It indicates that flame retardants make the yarn more responsive to tension.

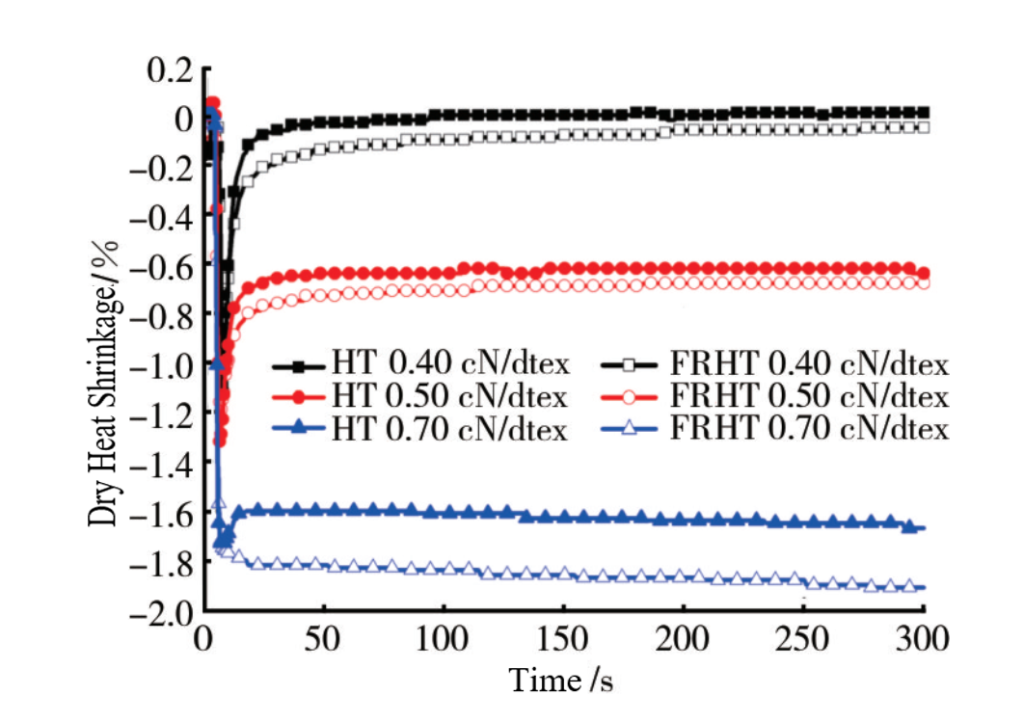

4. Dry Heat Shrinkage

Dry heat shrinkage measures the size stability of polyester industrial yarns. The study showed that at 0.40 cN/dtex pre-tension, FRHT’s dry heat shrinkage stayed stable at 195°C, indicating good size stability. However, too much pre-tension can cause negative shrinkage, where the yarn deforms. After high-temperature treatment, FRHT showed similar size stability to HT. They all keep high tensile strength and heat resistance.

5. Conclusion

- Performance of Flame-Retardant Polyester industrial yarns:

After treatment at 195°C, FRHT’s crystallinity, mechanical properties, and size stability were similar to HT. FRHT had strong tensile properties and good heat resistance.

- Effect of Pre-Tension:

Increasing pre-tension reduces the loss of amorphous chain orientation. But it improves crystallinity, orientation, and mechanical properties. When pre-tension is above 0.40 cN/dtex, FRHT’s strength and modulus are much higher than untreated samples. In practical applications, increasing pre-tension can reduce strength loss and improve the performance of high-strength flame-retardant polyester industrial yarns.

This research provides useful insights into the post-processing of industrial yarns. It helps to improve their performance while maintaining high flame resistance.

Note:The above data is sourced from Cotton Textile Technology.