When it comes to cationic polyester chips, we focus on the dye uptake, which is influenced by the third monomer. The third monomer, SIPM, plays a key role in cationic polyester chips. SIPM not only enhances the dyeing properties of the polyester but also improves its moisture absorption and softness. Therefore, understanding the reaction rate and effectiveness of SIPM is crucial for improving the quality of cationic polyester chips. This article will provide detailed information about the third monomer, SIPM.

1. What is SIPM?

SIPM comes from a reaction between SIPM (a chemical) and ethylene glycol. This reaction makes SIPM, along with two other chemicals, SIPME and SIPM. So, the SIPM solution usually has all three chemicals mixed with ethylene glycol.

2. How is SIPM Used?

SIPM helps make special polyester chips that can be dyed easily and fibers that dissolve in alkali solutions. The best results come when about 70% of the SIPM has reacted. SIPM can join together by itself if there’s too much methanol left in the reaction, causing problems when heated.

3. How to Test SIPM Reaction?

To check how much SIPM has reacted, we use a method called HPLC. This test uses a specific type of column and measures at 230 nm. The liquid for the test is a mix of methanol and water. This method helps in checking and controlling the quality of SIPM.

4. Using SIPM in Making Polyester Chips

SIPM has strong chemical groups that make it hard for the polyester molecules to move. This makes the mixture thicker. Adding PEG can help make the mixture flow better. PEG also helps dye stick to the polyester more easily.

5. Is More SIPM Content Better?

Adding more SIPM doesn’t always help. When too much SIPM is added, it becomes harder for it to mix well. For example, when 10% or 15% SIPM is added, most of it mixes well. But when 30% SIPM is added, only a part of it mixes well. Usually, the content of SIPM is from 2% to 5% in weight radio Or from 1.3% to 3.3% in mole ratio in textile industries. But irregular ones can be customized.

6. How Does SIPM Affect Intrinsic Viscosity?

As the content of the third monomer SIPM increases, the intrinsic viscosity decreases. When the SIPM feed content is at 10 wt%, the intrinsic viscosity reaches 0.54 dL/g. However, at 30 wt%, the intrinsic viscosity drops to only 0.35 dL/g. Although the addition of PEG is beneficial to the copolymerization and grafting of sodium sulfonate groups on the molecular chain. But, the introduction of excess SIPM will lead to obvious steric hindrance. It makes copolymerization difficult, resulting in a low actual copolymerization rate. Why IV is so important, I have written an article to introduce, please click here.

7. How Does SIPM Affect Water Absorption?

High-content cationic dye-dyable polyester chips show strong water absorption capacity. Through moisture absorption and water absorption test, it can be seen that with the increase of the content of the three monomers, its water absorption and moisture absorption rate increases.

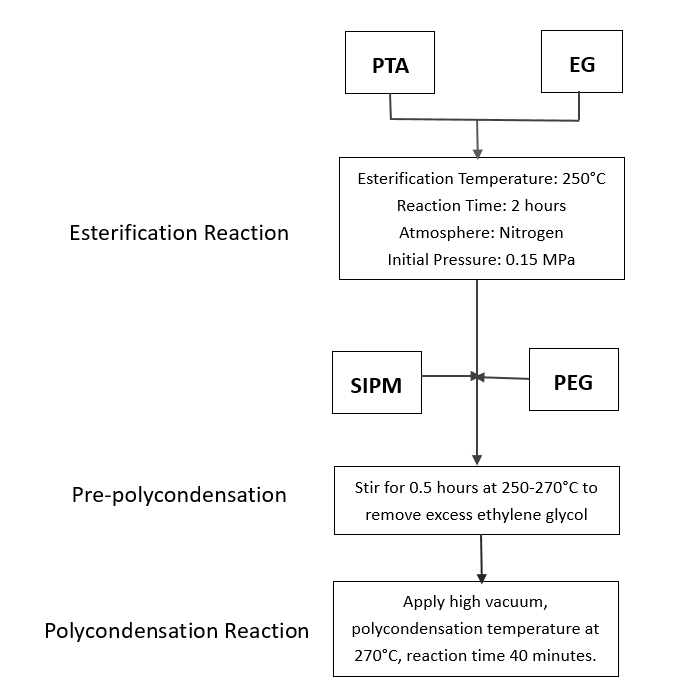

8. Preparation Process Of Alkali-Soluble Polyester Chips Using SIPM

9. Where to Use SIPM?

SIPM is important for making polyester chips that can be dyed easily and fibers that dissolve in alkali. It helps dye stick to the fibers better, improving the quality and performance of the final product. Its chips can used to produce spinning of POY, FDY and short-staple fiber. Also, it can be blended and interwoven with any synthetic fiber, man-made fiber, or natural yarn.

Summary

SIPM is crucial in making polyester fibers. Controlling how much SIPM reacts improves its performance in products. Knowing how SIPM affects thickness and water absorption helps in making high-quality polyester and fibers.