When making furniture, people often prefer the natural look of wood. Traditionally, wood grain is achieved by applying wood grain paper to the board. This is then achieved by applying layers of paint and gloss. But, printing has made its way into furniture. Now, patterns can be printed directly onto PET film, coated with an adhesive. Then transfer to the plate by heat.

Globally, Germany is known for producing the best heat transfer films. Their films are used not only in home furnishings but also in automotive interiors. Their price is RMB 60-80/㎡. Other notable producers include South Korea, Japan, and Taiwan. Their price is RMB 10-20/㎡.

PET thermal transfer film is widely used in the decoration of PVC foam boards, WPC boards, PS boards, and PPMA edge strips. Thermal transfer film technology is becoming more and more good. So indoor mold decoration has become a rising trend.

1. What is Heat Transfer Film?

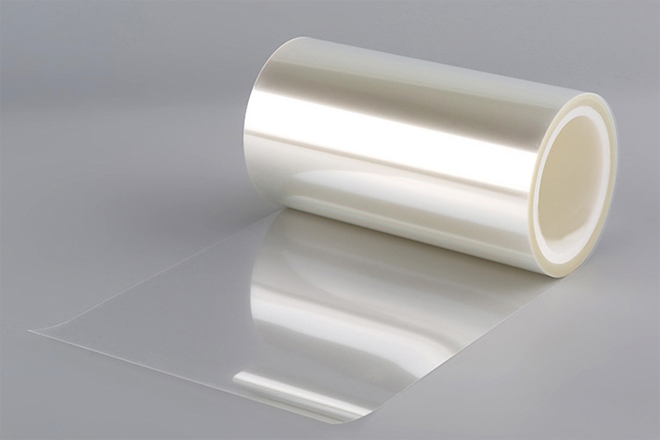

Heat transfer decoration involves heating the heat transfer film. The decorative pattern is transferred onto the surface of the building material in one go. During the heat transfer process, the protective layer and pattern layer are separated from the polyester base film. The heat-sensitive adhesive permanently bonds the entire decorative layer to the substrate. The heat transfer film consists of a polyester film as the backing paper with a wood grain decorative layer printed on it. It has layers of protective coating, base color, peel-off layer, and heat-sensitive adhesive.

It uses a high-temperature silicone roller to apply heat and pressure. Then it transfers layers to the surface of wood-based panels or furniture components. So it forms a decorative surface with excellent properties, such as wear resistance, heat resistance, and light resistance.

2. Applications of Heat Transfer Film Products

2.1 MDF Transfer Film

Applicable Areas: Products made of PVC, PS, ABS, PP, and other plastics.

Product Features: Realistic wood texture, three-dimensional effect, and the appearance of real wood.

Applications: Decorative panels, edge bands, interior doors, windows, and photo frame edges.

2.2 WPC Transfer Film

Applicable Areas: Products made of PVC, PS, ABS, PP, and other plastics.

Product Features: Realistic wood appearance, water resistance, corrosion resistance, anti-moth, and anti-mold.

Applications: Skirting boards, panels, furniture, composite flooring, and kitchen utensils.

2.3 Heat Sublimation Film

Applicable Areas: Stainless steel, aluminum-plastic panels, metal sheets.

Product Features: Rich colors, abrasion resistance, corrosion resistance, and exceptional durability.

Applications: Doors, windows, aluminum profiles, and security doors.

2.4 Glass Transfer Film

Applicable Areas: Glass, mirrored surfaces, and other surfaces.

Product Features: Replaces spray painting with a one-time heat transfer, no additional processes are required.

Applications: Interior decoration, furniture, glass cabinets, and curtain wall glass.

2.5 Floor Tile Transfer Film

Applicable Areas: Solid wood flooring, laminate flooring.

Product Features: Replaces real wood veneer and stickers, directly transferred onto the floor.

Applications: Solid wood flooring, laminate flooring.

3. Usage Parameters

Heat transfer films have unique properties. Achieving the ideal hot stamping effect requires strict control of temperature, pressure, and speed. Three crucial process parameters are:

3.1 Temperature Determination

Must consider factors such as pressure, speed, area, and room temperature. The stamping temperature generally ranges from 140°C to 180°C.

3.2 Pressure Determination

Stamping pressure is typically between 4 to 6 kg/cm2. Inadequate pressure reduces adhesion. While excessive pressure can cause compression deformation and pattern distortion.

3.3 Speed Determination

It depends on the stamping area and the power of the heating temperature. Generally, speed is determined first, followed by pressure, and then temperature.

4. Precautions

Heat transfer film products should be handled with care and stored vertically. It should be stored away from heat sources at a temperature of around 25°C. The storage location should be cool, dry, and protected from moisture. Gas generation and chemical reactions may occur when used under high-temperature conditions. So, correct storage and handling are essential to protect against moisture, pressure, and secure storage.